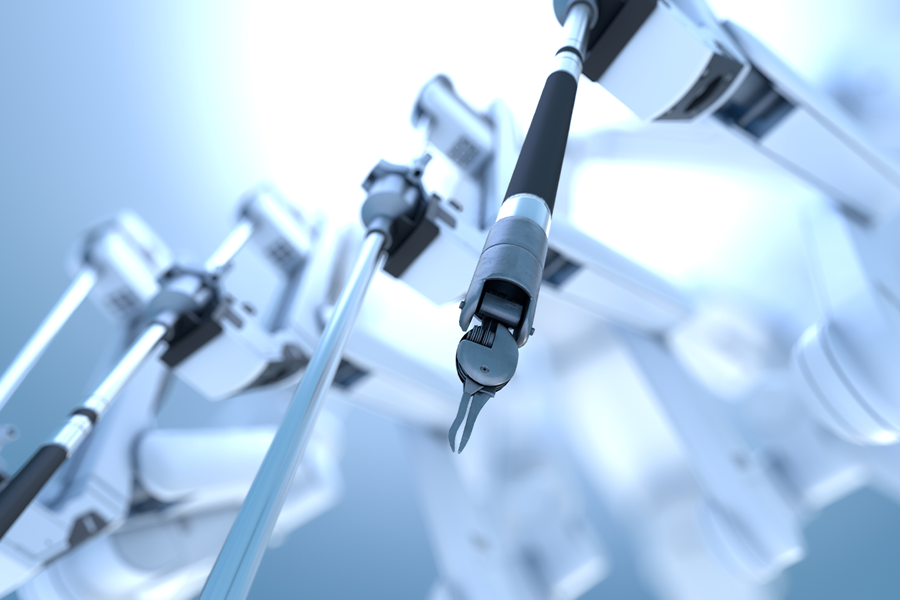

MIS/Robotic Surgery

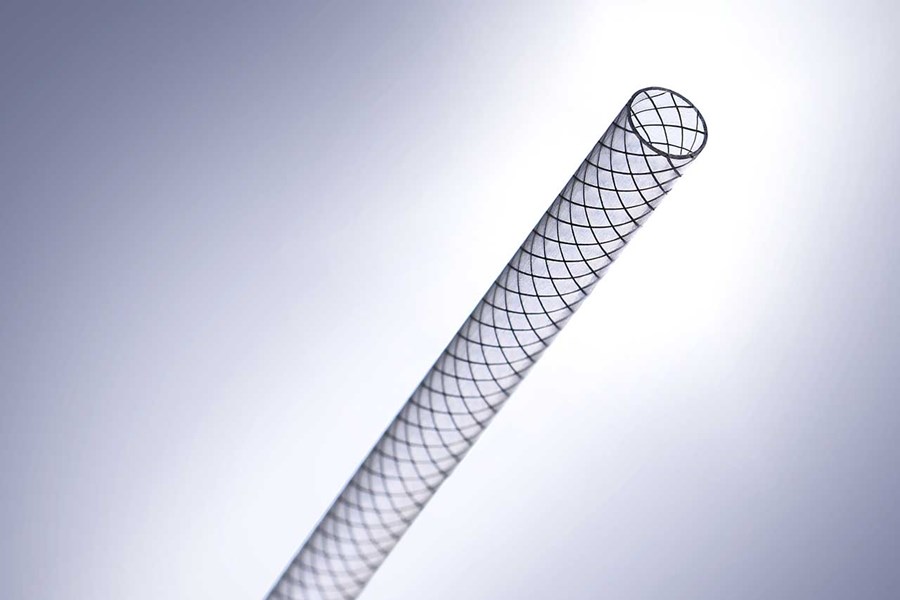

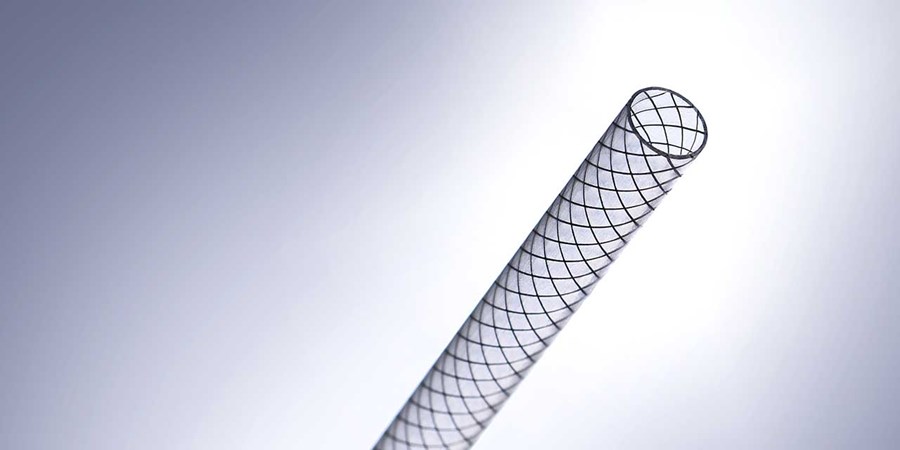

Robotic surgery involves the use of the latest technology and innovation in the medical device sector to conduct minimally invasive surgical operations. Spectrum's expertise with advanced polymeric component manufacturing precisely suits the needs of this trending product and application segment.

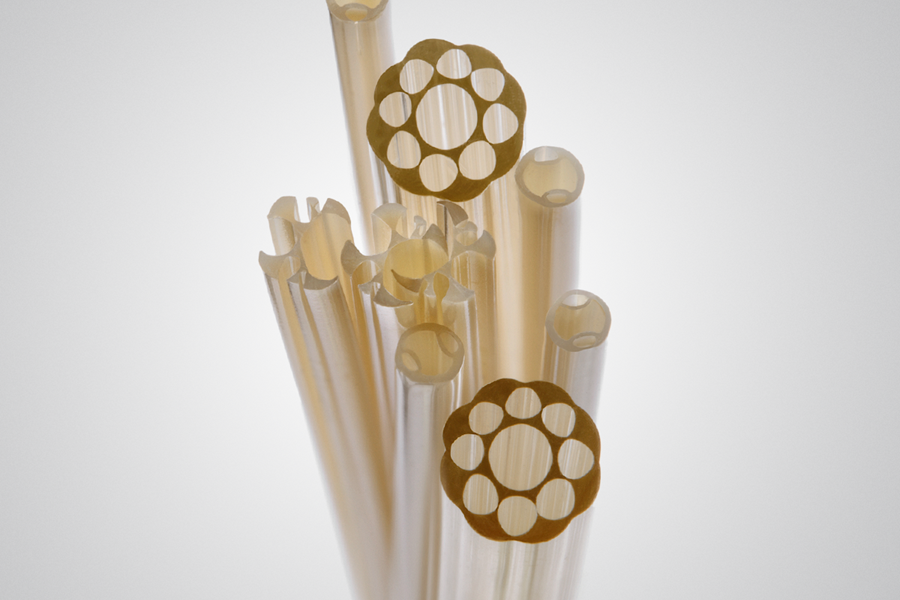

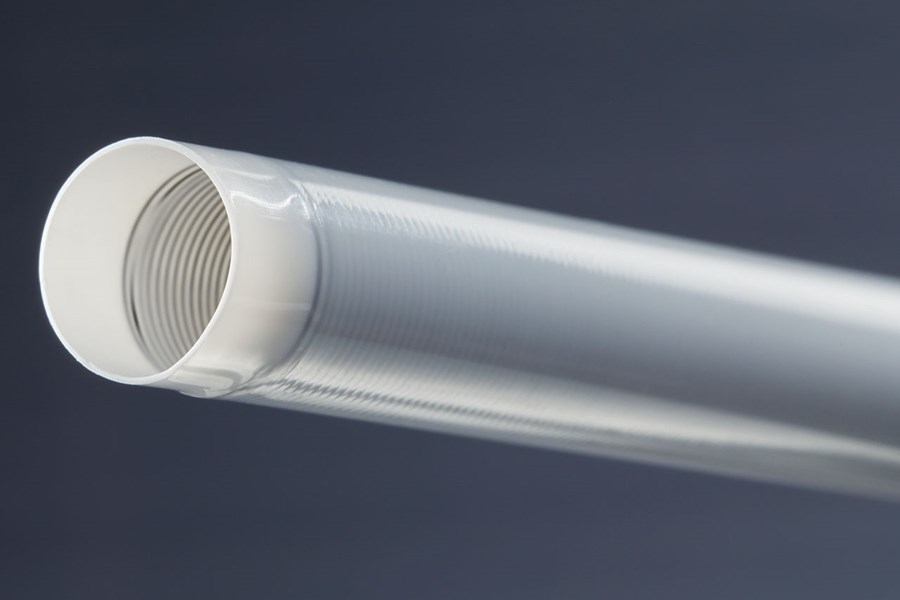

We fabricate critical molded components, products, and devices for a variety of surgical robotics applications, including steerable catheters, flexible shafts, multilumen extrusions, sterile draping film, and packaging.