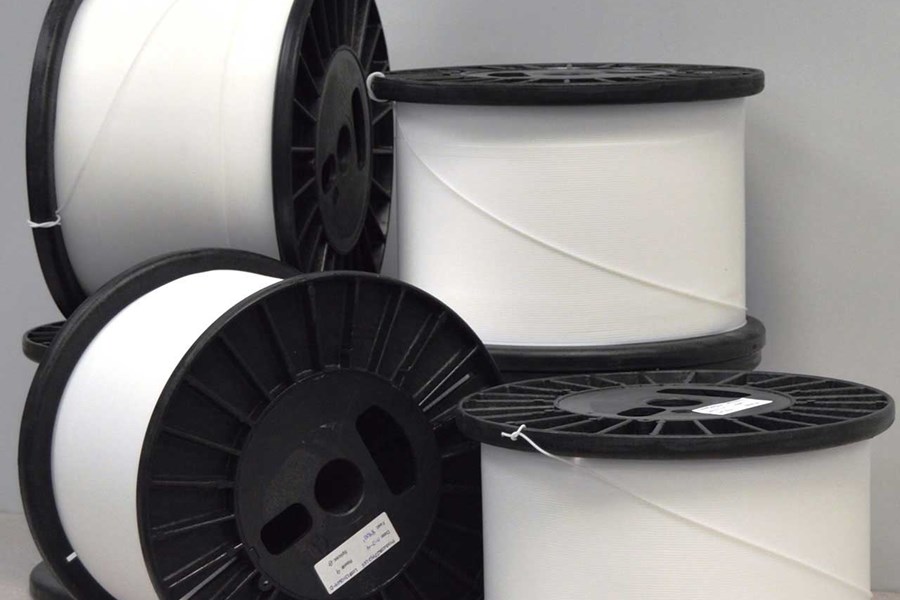

Core Mandrel

Used as a manufacturing aid in braid- or coil-reinforced catheter tubing, our core mandrels deliver extremely tight tolerances to ensure consistent diameter and roundness. Whether you’re working to develop a coiled or braided shaft with high-performance, the right core mandrel helps elevate process stability and product quality.

Core mandrels provide enhanced frictional control and improves release characteristics, delivering a lower release force during catheter manufacturing. Designed as manufacturing aid for coil and braided catheter shafts or tubing, our mandrels specialize in supporting tight tolerances and repeatable processing.

Material Options:

Specifications

Speed up development of your braid- or coil-reinforced catheter tubing with our quick-turn Core Mandrel program. We provide precision-machined acetal or silicone-blend mandrels, ready for immediate use in extruded tubing and solid rod setups — built and shipped within five calendar days (expedited fee applies).*

Program Details:

Download One Pager

Acetal mandrels are used as a manufacturing aide for braid or coil reinforced catheter tubing.

We’re happy to help with your projects in any way we can. Contact us and we’ll email you back the information you’re looking for, or we’ll schedule a call to discuss with you in more detail.