Quality & Regulatory Support

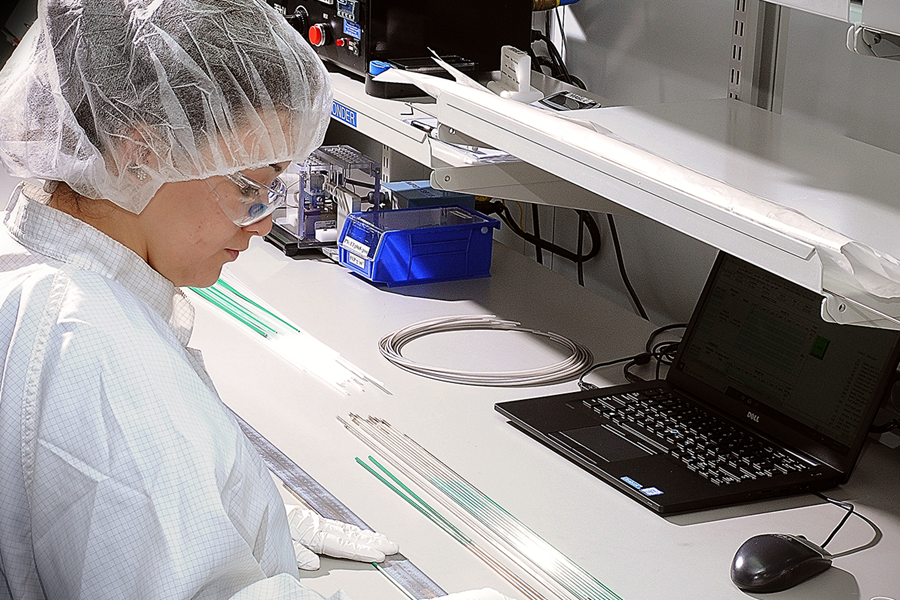

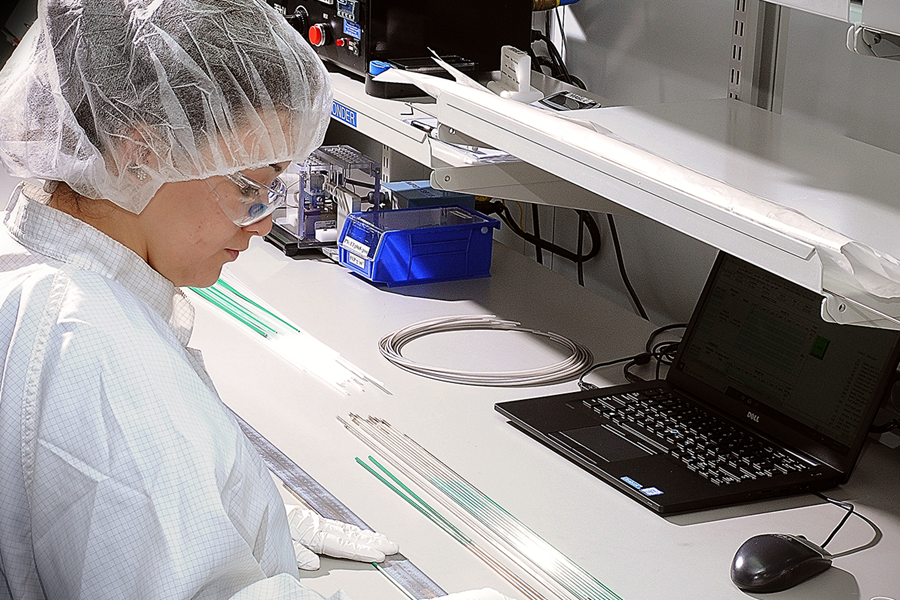

Whether you’re developing a Class I, Class II, Class IIb, or Class III medical device, we can work with you to optimize your product for manufacturability, reliability, safety, regulatory compliance, and competitiveness.

Quality & Regulatory Support

Whether you’re developing a Class I, Class II, Class IIb, or Class III medical device, we can work with you to optimize your product for manufacturability, reliability, safety, regulatory compliance, and competitiveness.

Our Enterprise Quality Management System provides the tools, systems, and procedures to ensure that we deliver unparalleled manufacturing results and customer satisfaction consistently at our 19 manufacturing sites across 6 countries.

ISO Certifications

FDA Registered

ITAR and AECA Compliant

We can manage the complete approval process for your Class II, Class IIb, or Class III medical device program. Our dedicated team is well-versed in the requirements of regulatory bodies worldwide.

Services include:

Lean Manufacturing is a strategic initiative to help our company to work smarter, to be more efficient, and to eliminate defects. From the factory floor to the leadership team, the Lean culture shapes how we run our business and is incorporated into the entire product lifecycle.

In-House Metrology Lab

Process Improvement Methodologies