Strong upfront engineering decreases time-to-market & capital costs

Strong upfront engineering decreases time-to-market & capital costs

A mid-size, market leading orthopedics company working in the “Memory Metal” field was acquired by a Fortune 50 Medical Device Company. The product line that they had introduced was injection molded using prototype molds without any validated molding processes. This approach produced extremely high scrap rates and a continuous need to replace the prototype molds. Several suppliers were approached as potential partners, each one asked to develop a long-term strategy for the program.

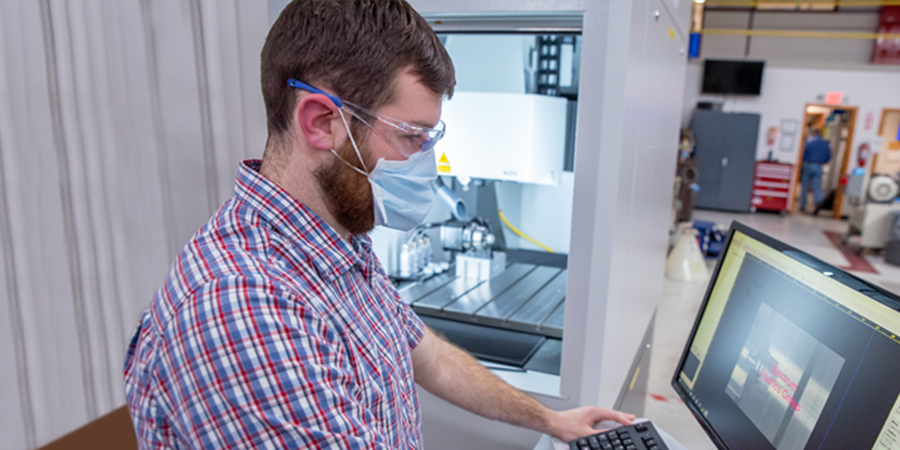

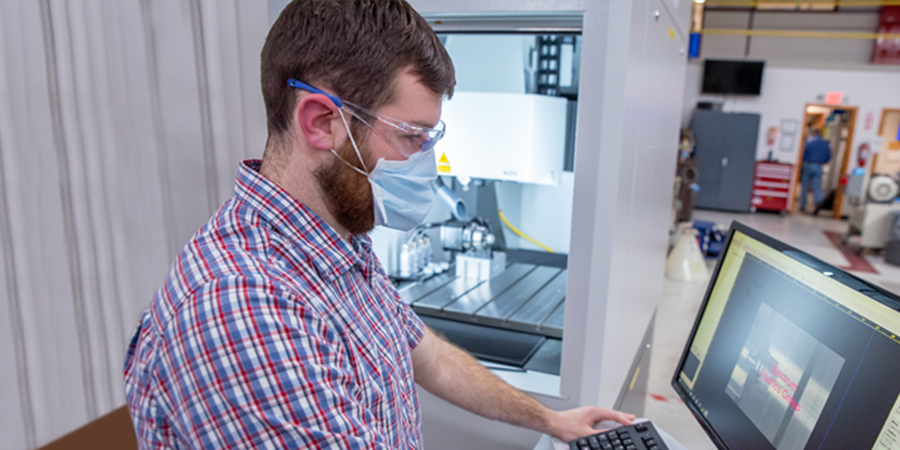

The Spectrum Plastics Group Solution

The customer’s program consisted of 96 separate SKUs and the majority of the proposals were based on 96 individual molds and validations. Our Pittsfield, Massachusetts operation, considered the program based on a family approach, developing SKU stacks that would share common mold bases. We also proposed validating by family, bookending the largest, medium & smallest sizes within a family of components.

In order to achieve this objective, Spectrum performed a considerable amount of “Design for Manufacture” engineering activities along with active collaboration amongst the customer and internal technical teams With this approach, Spectrum was able to condense the program into 24 molds, which share component stacks to produce the 96 individual SKUs. We were also able to reduce the validation number to 32 families versus 96 individual SKUs.

Outcome

Our Upfront Engineering approach successfully reduced the potential capital and validation cost by over 60% over conventional tooling/validation strategies. This also saved up to twelve months of time for product release. All molds are complete and we are now in the final validation stages for the program. The strategy implemented by Spectrum is an excellent example of utilizing In-House Engineering solutions throughout the process, from Product Design, to Validation to Production Molding.

Customer Testimonial

“The Spectrum team has been nothing short of excellent to work with. I acknowledge the Project Manager has been a great help to our company’s project and I thank him for his efforts day in and day out. Along with him, the Design Engineers and great to work with and made it easy to communicate with and share ideas despite being located in different sections of the country. Overall, great job from the entire Spectrum team working us on our project.”